Press seals

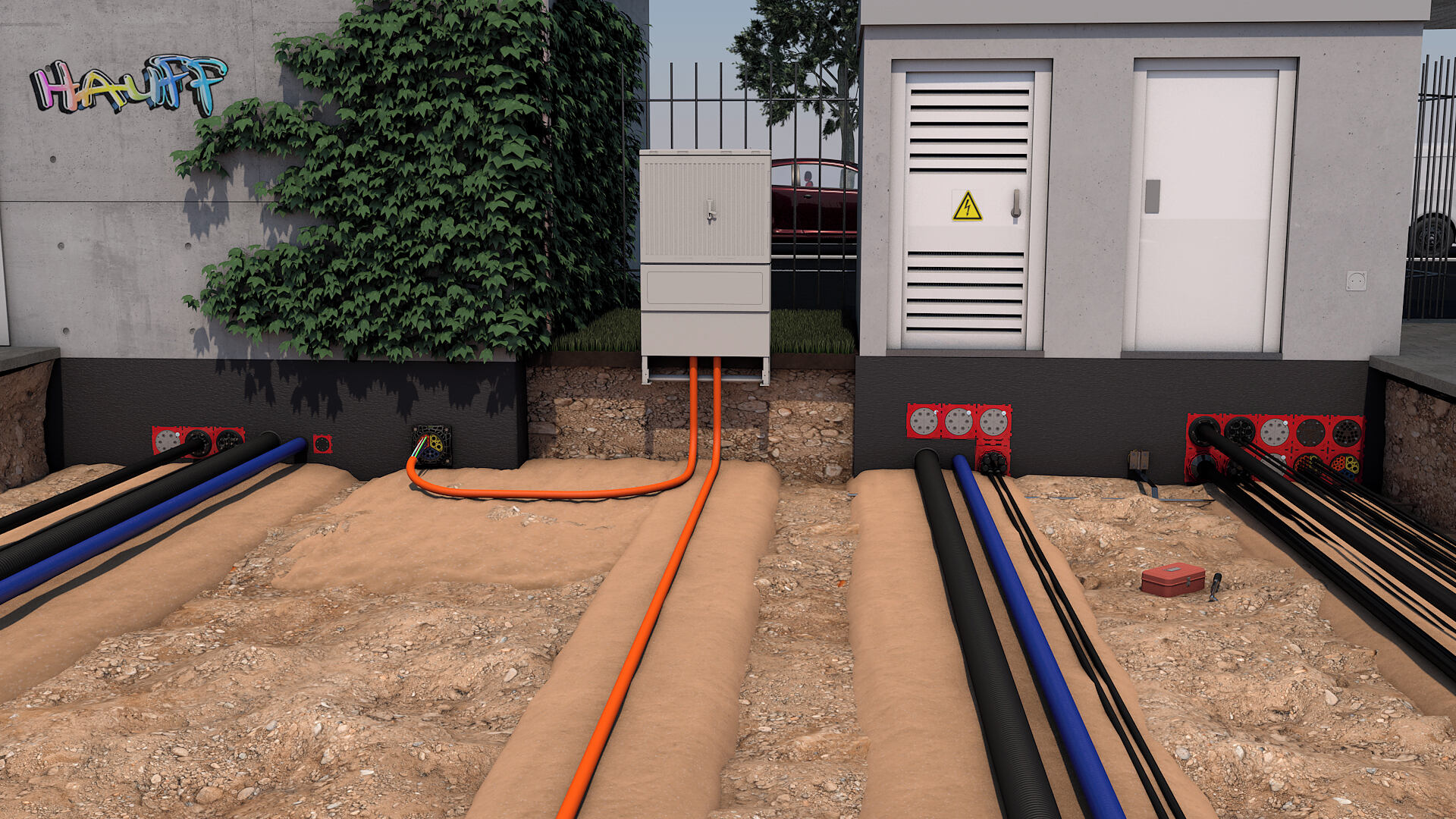

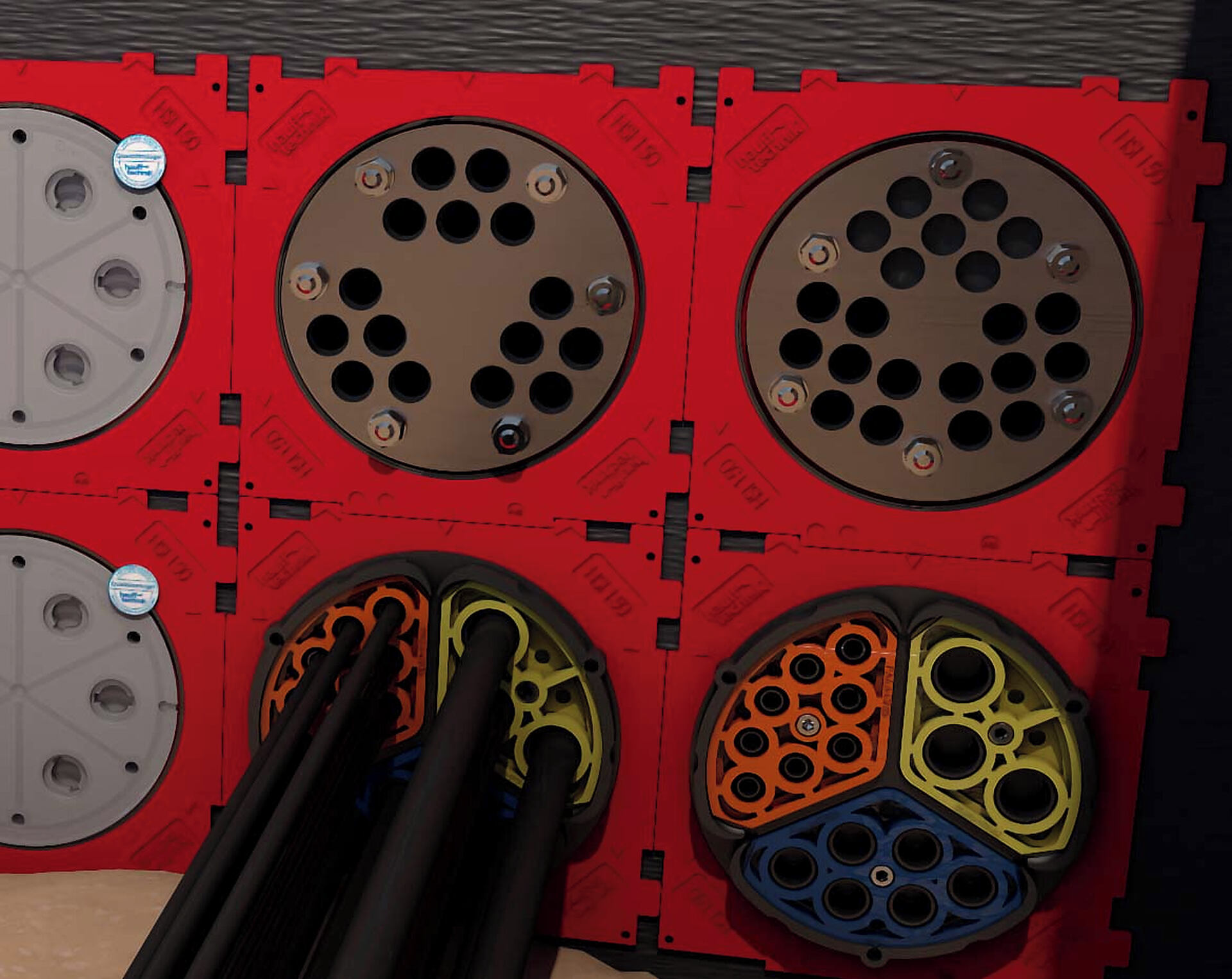

The innovative press seals from Hauff-Technik provide you with every possible opportunity for reliable sealing of core drills or wall sleeves for one or a number of cables.

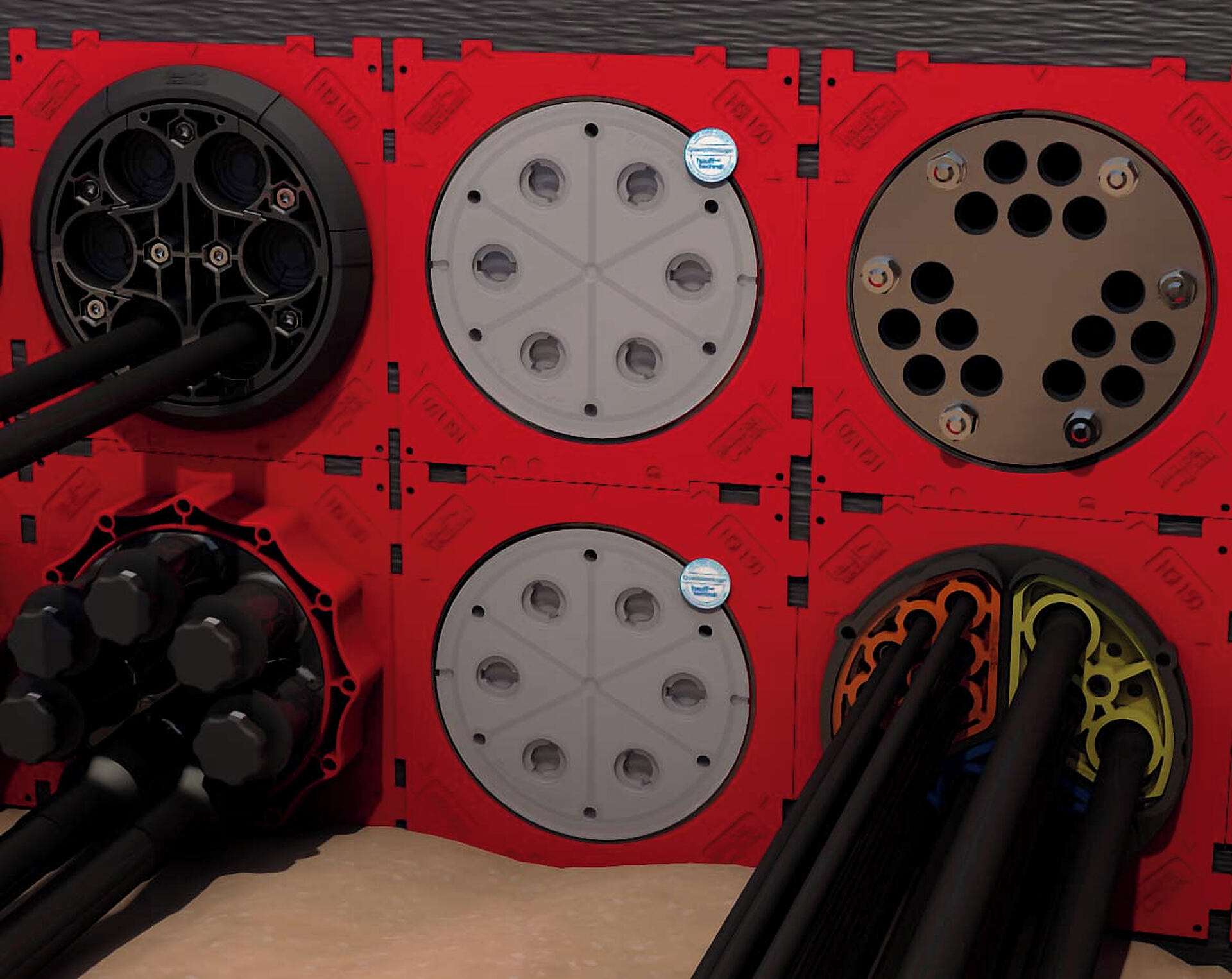

These range from closed seal inserts for first-time installation to split seal inserts for retrofit sealing of cables that have already been laid. We can provide the ideal press seal for every requirement and task, be it tailor-made to the millimetre or suitable for universal use on site, round, oval or even square. Quick and cost-effective.

Standard

Standard press seal

with segmented ring technology

HRD SG b40 A2/EPDM

Standard press seal

with super segmented ring technology and polymer press plates

HRK SSG b40 PAGF/A4/EPDM

Standard press seal for internal sealing of corrugated pipes

with segmented ring technology

WIN SG b40 A2/EPDM

Standard press seal

for building connections

HSD100 EW 1x24-44+4x7-12 b40 A2/EPDMCustom

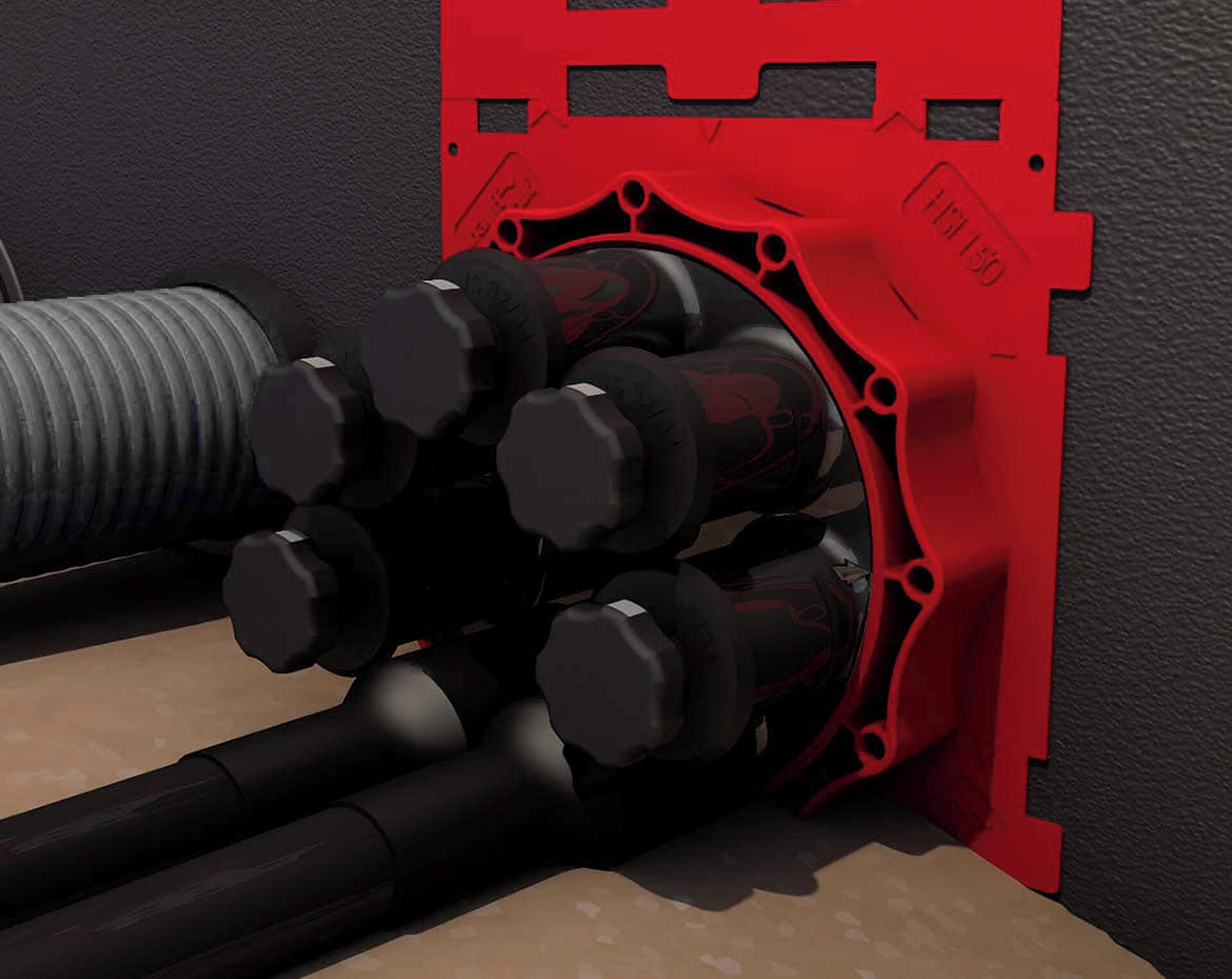

Transforming Core Drills or Sleeve Pipes into Flexible Building Entries with Annular Seals

Core drilling is frequently utilized when retrofitting building entries. In such cases, practical and effective sealing solutions for the created holes and the supply lines introduced are necessary. The same applies when utilizing sleeve pipes. Hauff-Technik’s press seals are the ideal solution for these situations, ensuring a durable and leak-proof seal that meets industry standards.

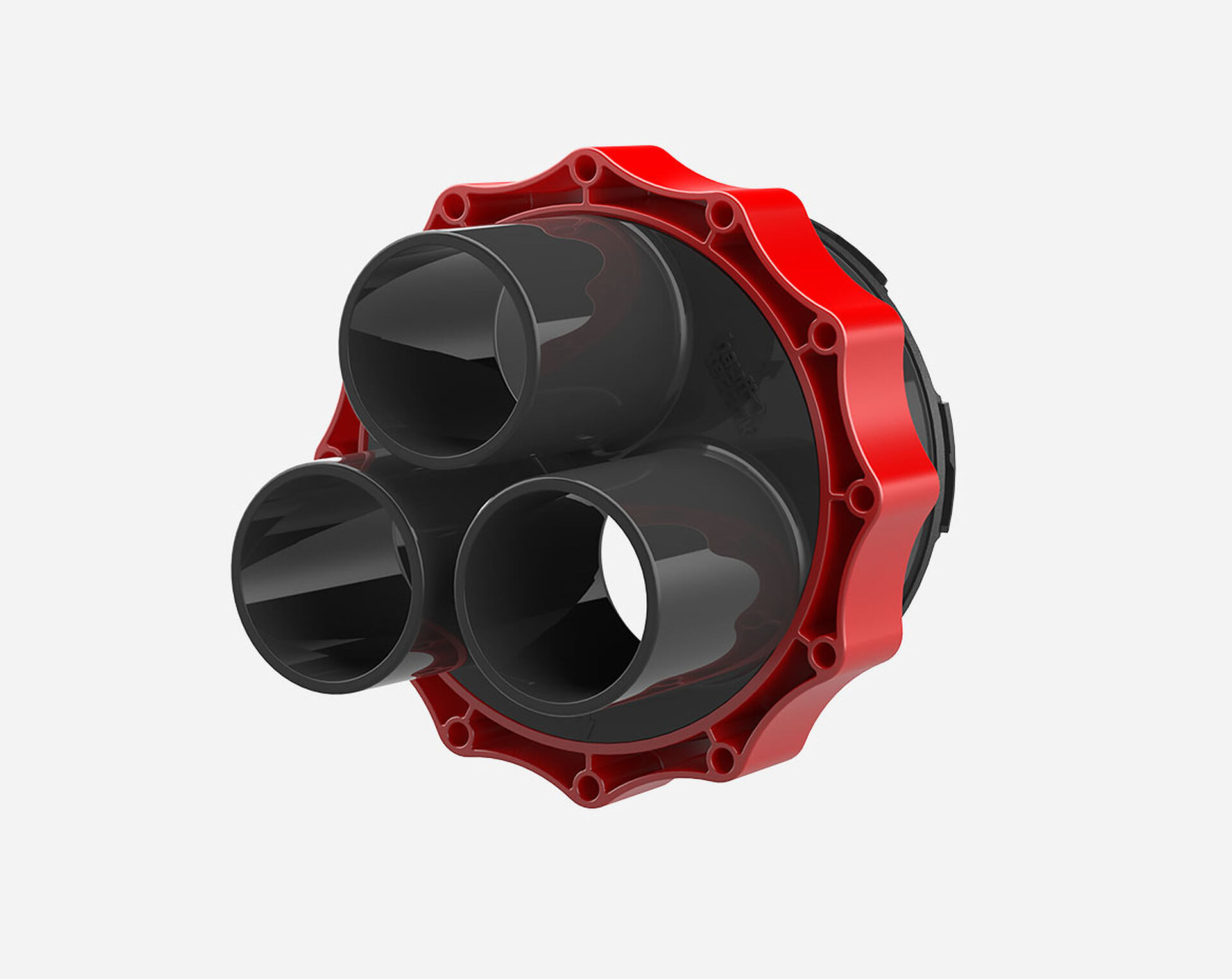

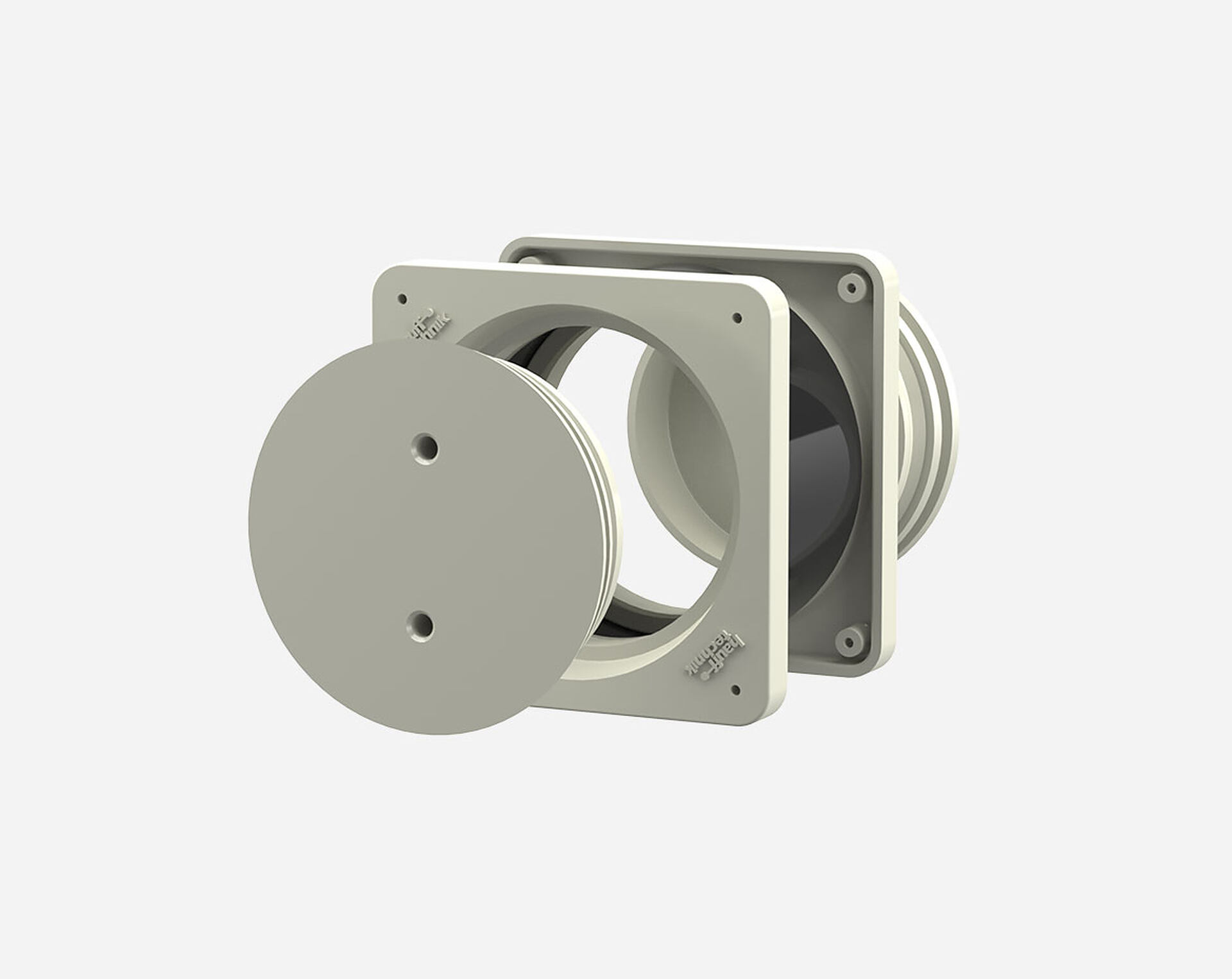

The Functional Principle of an Annular Seal

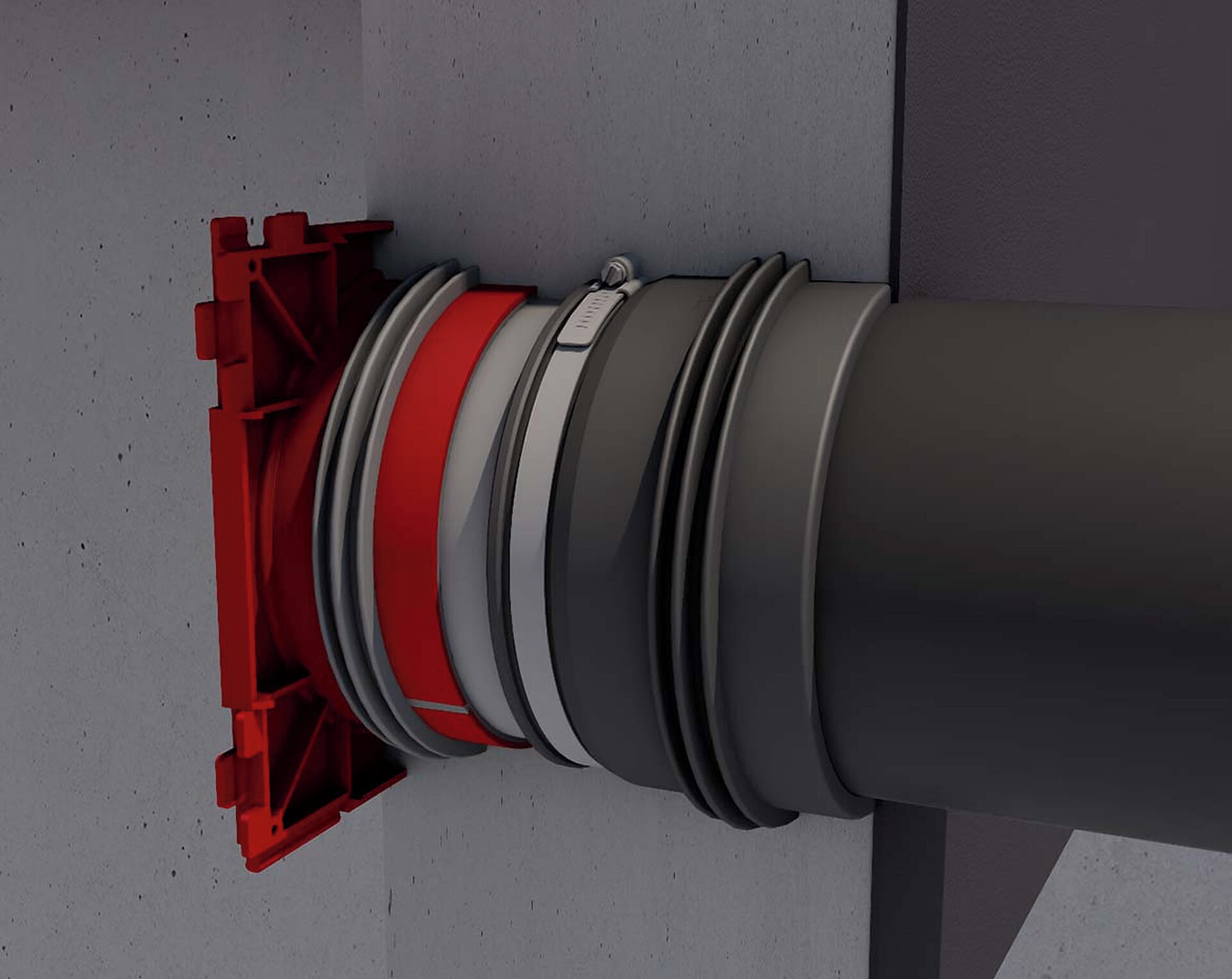

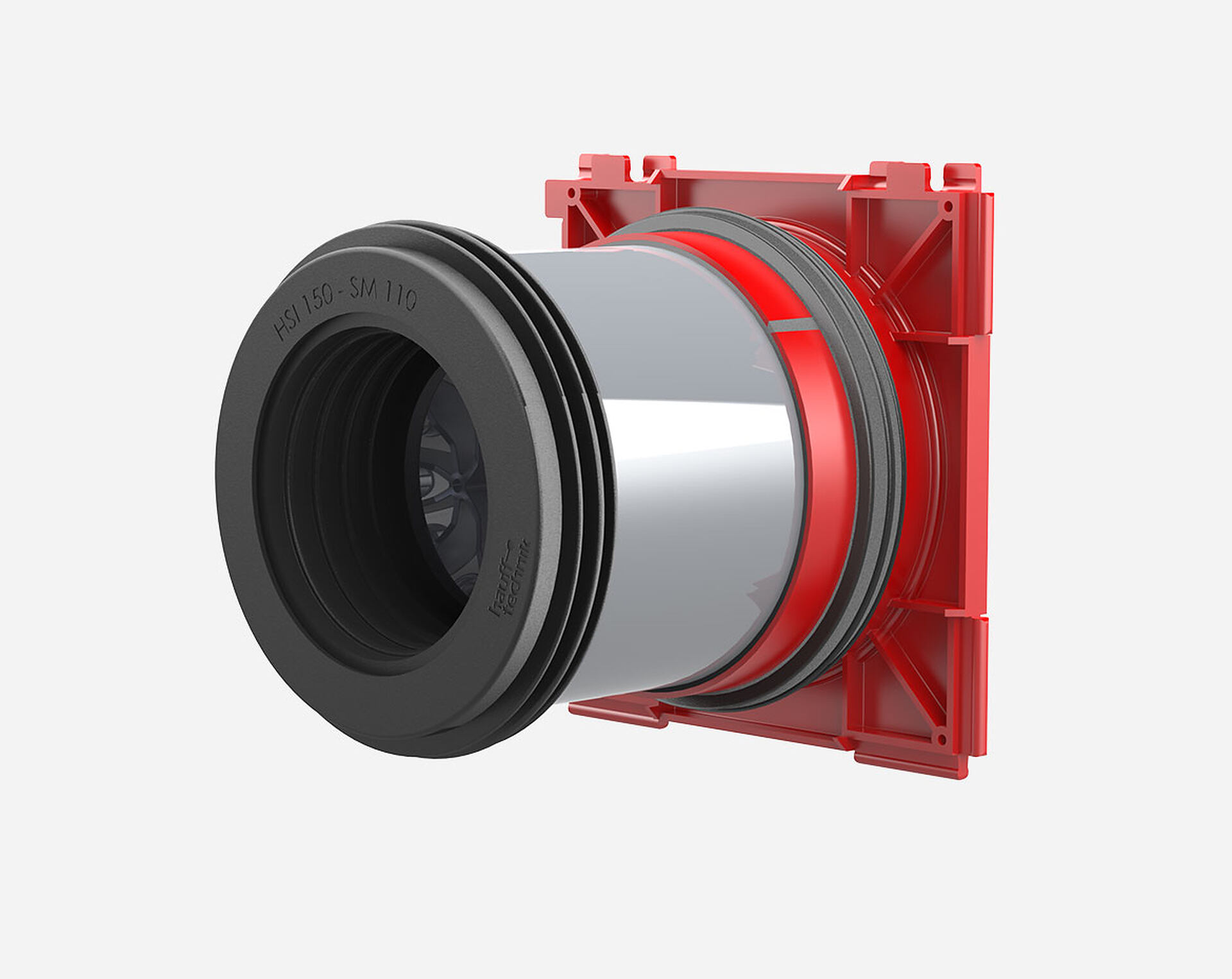

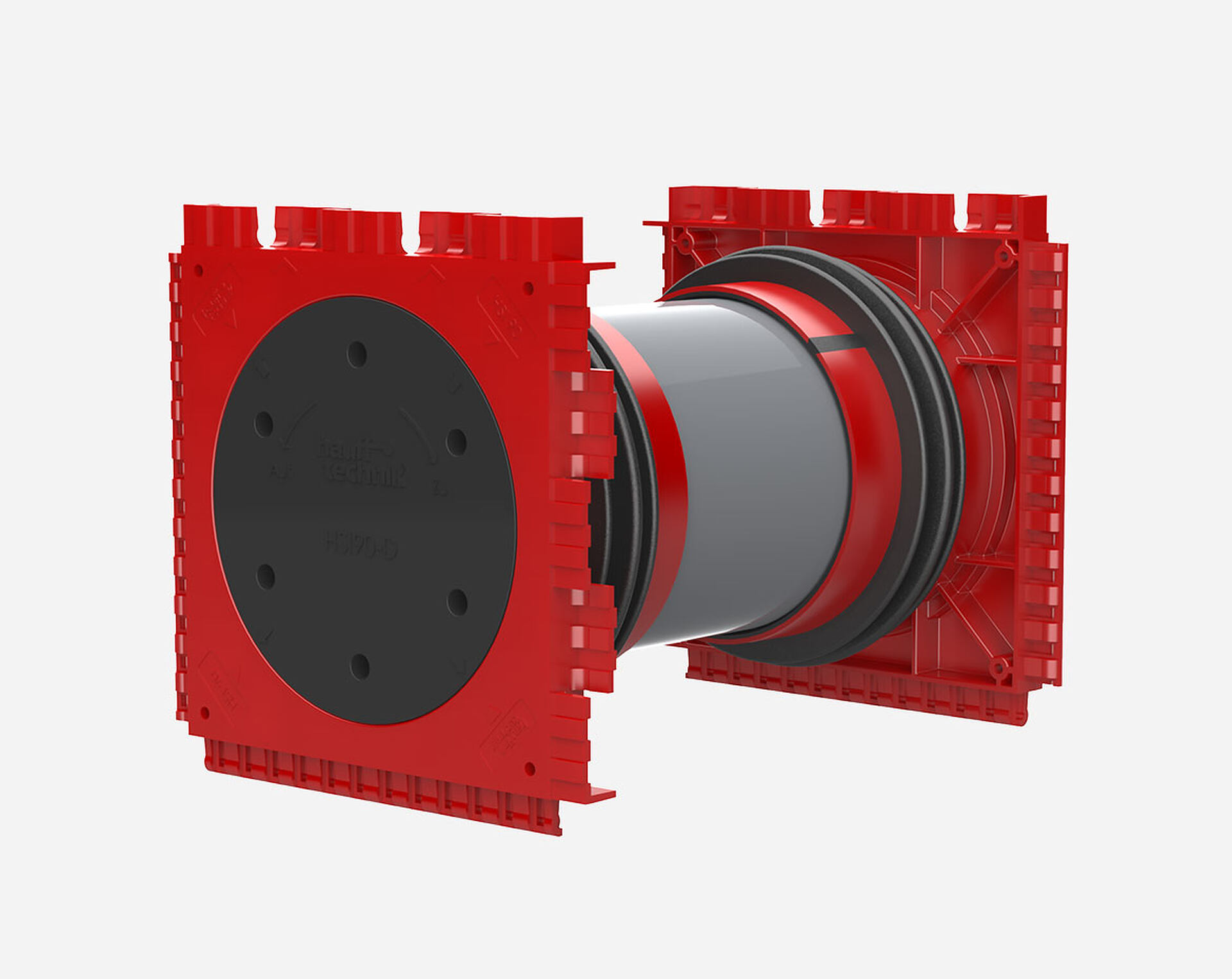

A press seal is particularly effective for installation in already existing wall penetrations, such as those resulting from core drilling or when utilizing sleeve pipes. The outer component comprises a rubber compression seal that ensures a gas-tight and water-tight fit to the building.

The design of the press seal includes several sealing inserts, enabling the passage of individual supply lines. Additionally, each cable and pipe entry is sealed independently, guaranteeing they are both gas-tight and water-tight.

This system allows core drillings and sleeve pipes to be transformed into multifunctional entry points for supply lines. As a result, it facilitates the introduction of various cables and pipes, while also allowing for future expansions. This ensures that Hauff-Technik’s solutions provide a high level of adaptability and future-proofing.

Diverse Product Range – Press seals from Hauff-Technik

Hauff-Technik offers innovative solutions for core drillings and sleeve pipes, available in diameters from 50 mm to 200 mm. The press seals support a diverse range of supply lines, with larger models serving as KG pipe seals and smaller options designed for electrical and telecommunication cable installations into buildings.

The standard press seal for house connections is engineered for core drillings with a diameter of 100 mm, enabling up to five connections for various lines. Hauff-Technik employs segment ring technology in their annular seals, facilitating on-site adjustments tailored to the specific diameter of the lines. Standard connections are compatible with lines measuring 7 mm to 12 mm in diameter.

For sealing pipes, larger gaps can be efficiently addressed with link chain seals. This method is particularly effective for KG pipe seals and can be applied to any diameter or type of pipe due to its flexible design. Link chain seals also ensure gas-tight and water-tight connections for houses. The sealing process between core drillings and press seals involves a rubber compression seal.

Our seals featuring segment ring technology are designed with split seals, allowing for post-installation adjustments. This setup can safely accommodate up to ten supply lines routed through a single core drilling into the building. It supports both small lines with a 4 mm diameter and larger supply lines with up to 110 mm cross-sections.

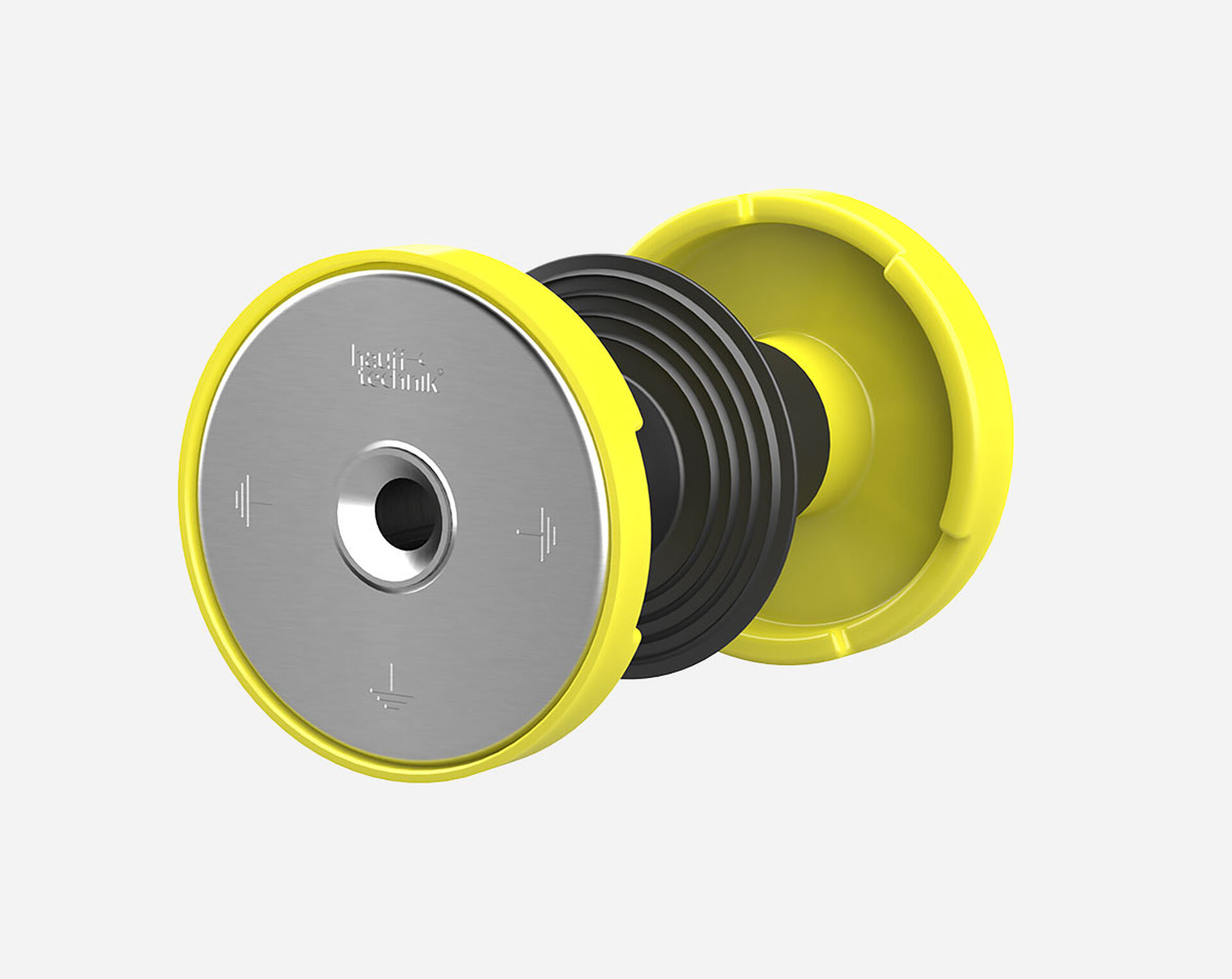

Additionally, blind seals are part of the press seal category, allowing for the quick and secure closure of sleeve pipes or core drillings. These seals cater to openings and pipes with diameters from 20 mm to 107.5 mm and can be installed without tools, requiring only two hand movements. A sealing flange provides pressure closure, ensuring that unused core drillings or sleeve pipes are sealed gas-tight and water-tight. These can be repurposed later for various supply lines.

Blind seals are aswell part of the press seal category, allowing for the quick and secure closure of sleeve pipes or core drillings. These seals cater to openings and pipes with diameters from 20 mm to 107.5 mm and can be installed without tools, requiring only two hand movements. A sealing flange provides pressure closure, ensuring that unused core drillings or sleeve pipes are sealed gas-tight and water-tight. These can be repurposed later for various supply lines.

Custom-Made Press seals from Hauff-Technik

In the field of cable and pipe penetrations, it is common for standard solutions to fall short of necessary characteristics. To combat this, Hauff-Technik provides the option for bespoke manufacturing of press seals based on customer specifications. This allows for adjustments to cable diameters directly on-site.

Hauff-Technik's bespoke sealing systems cater to microtubes and conduit pipes, and they also incorporate segment ring technology. These press seals can be created with covering sealing flanges or configured for multiple and mixed applications. Additionally, eccentric designs can be accommodated. If required, both closed and split versions can be produced. Customized solutions are available for core drillings and sleeve pipes with diameters ranging from 40 mm to 200 mm at Hauff-Technik. The finished components are delivered with millimeter precision.

Help us improve our website service.

Where would you place yourself?

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة