Earthings

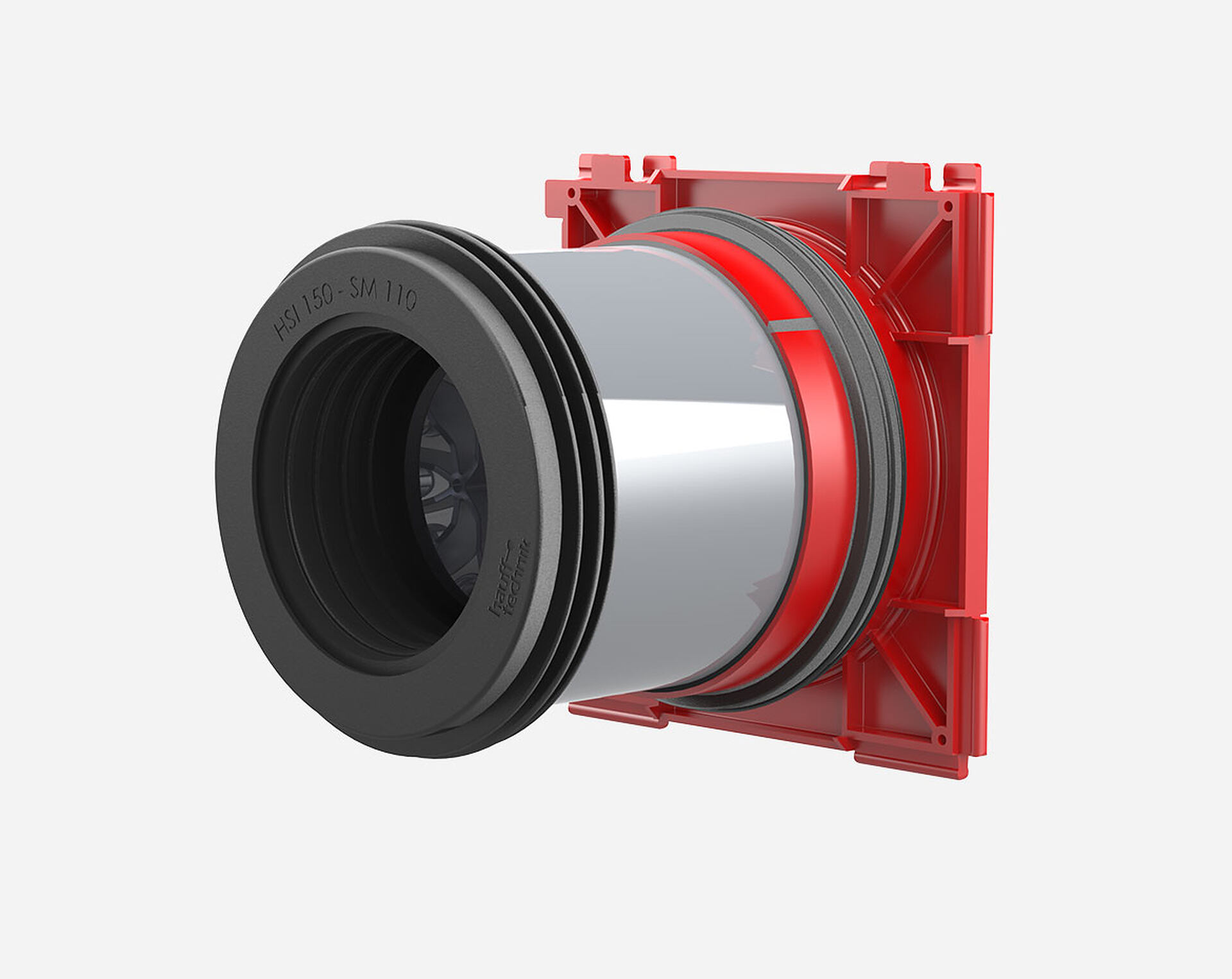

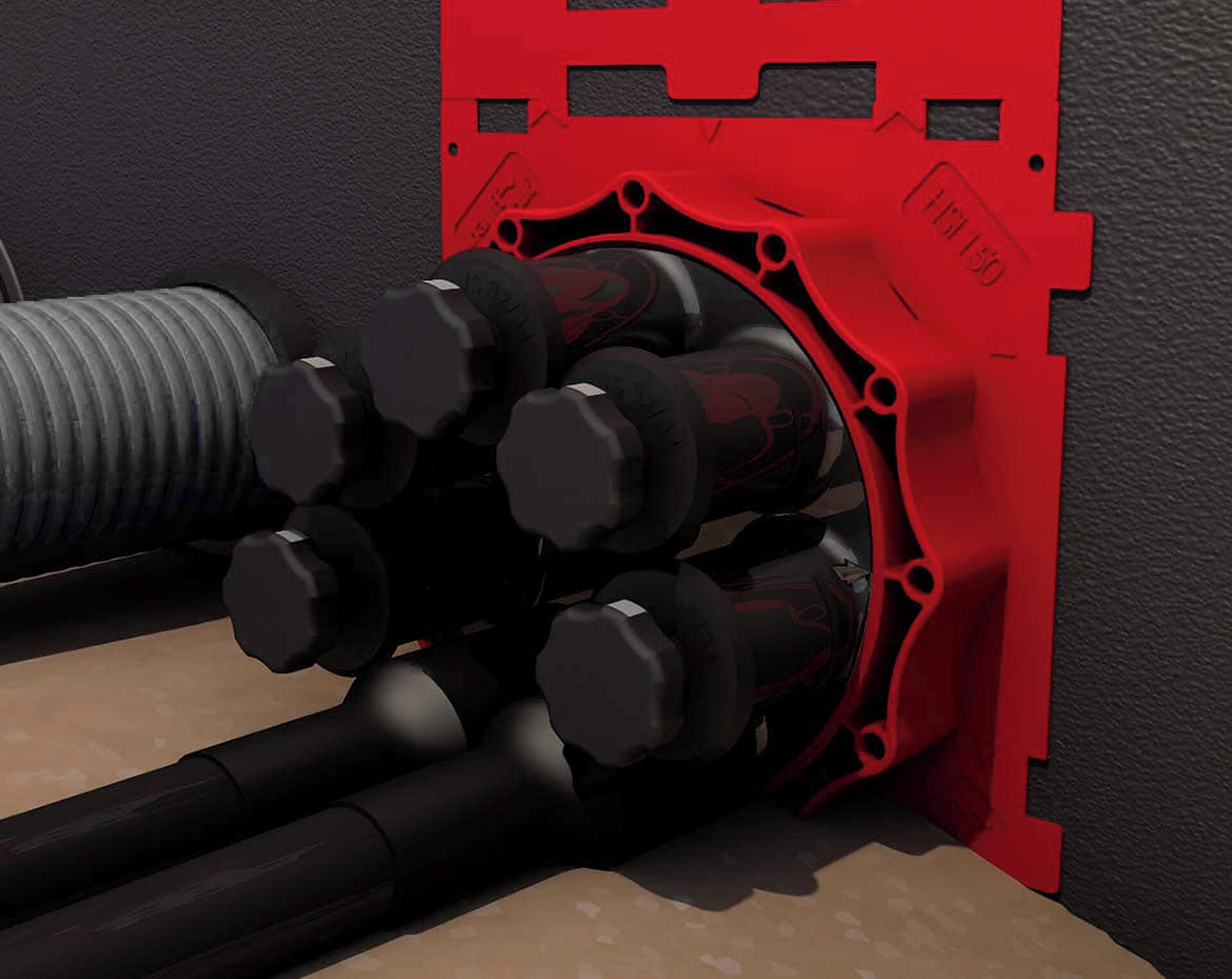

HEA earthing connections are available for delivery as entries or earthing fixed points in various designs to meet prevailing requirements. Both solutions for installation in concrete walls flush with shuttering and solutions for retrofitting in drill holes are available. Hauff-Technik offers an insulated earthing entry specifically for station construction. The earthing connections, which are manufactured in stainless steel to the highest quality standards, maintain their function throughout their service life. They are used for protective earthing, functional earthing, operational earthing and lightning protection earthing, for example.

Inserts / new construction

Earthing wall collar

for round and flat conductors

HMK

Earthing entry

HEA

Earthing fixed point

with welding groove

HEA A

Earthing entry

for double walls/element walls

HEA EW

Insulated earthing entry

HEA IS

Earthing fixed point

with cross-clamp

HEA P

Flexible earthing entry

HEA PF

Earthing entry

with connecting lug and cross-clamp

HEA PK

Earthing fixed point

for weld or clamp connection

HEA S

Earthing entry

for building entry according to DIN 18533 (black tank)

HEA WInserts / subsequent installation

Hauff-Technik Solutions for Grounding Inlets in Buildings

Grounding systems in buildings are vital for safety. Different grounding methods exist, such as protective, functional, operational, and lightning protection grounding. Hauff-Technik offers a range of solutions suitable for all grounding inlet types, ensuring your building meets safety standards.

The Role of Grounding in Safety

Grounding serves crucial functions in protecting both people and buildings. It mitigates the risks associated with malfunctions or electrical surges from systems, whether triggered by lightning strikes or technical errors. The grounding connection operates on a simple principle: a metal wire or component creates a permanent bond with the earth. Through this connection, surges are channelled into the ground, a method known as potential equalization. Different building techniques require specific grounding inlets, and Hauff-Technik provides effective solutions for every circumstance, whether for new constructions or retroactive grounding applications.

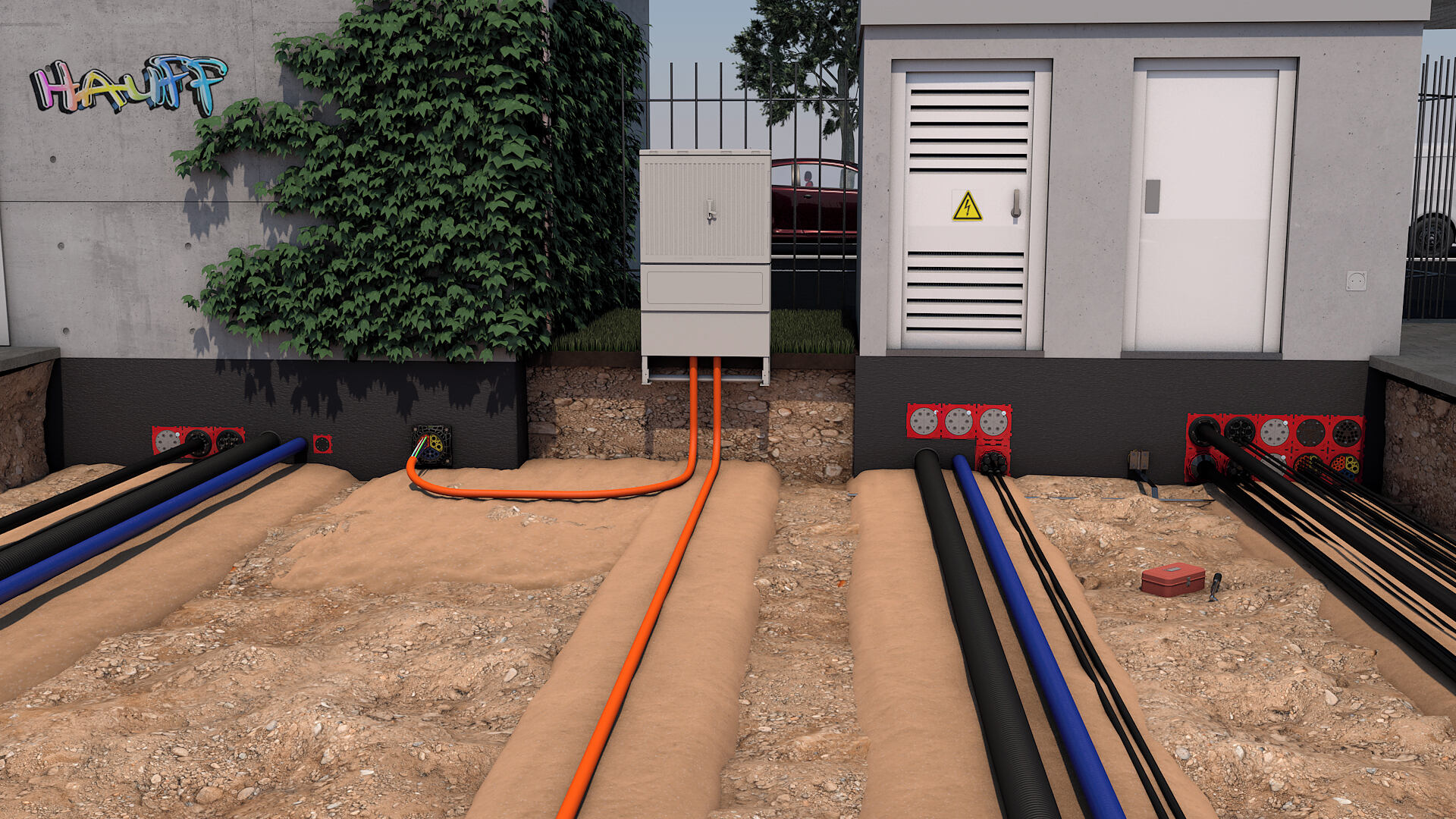

Simplifying Site Power Supply Entries

In new constructions, the electrical wiring comprises various components. The electrical house connection is typically executed underground during the building phase. This is followed by the grounding connection, which integrates with the electrical system, telecommunications lines, and lightning protection systems. Hauff-Technik offers all necessary construction components to help you implement your building project professionally, efficiently, and at a reasonable cost.

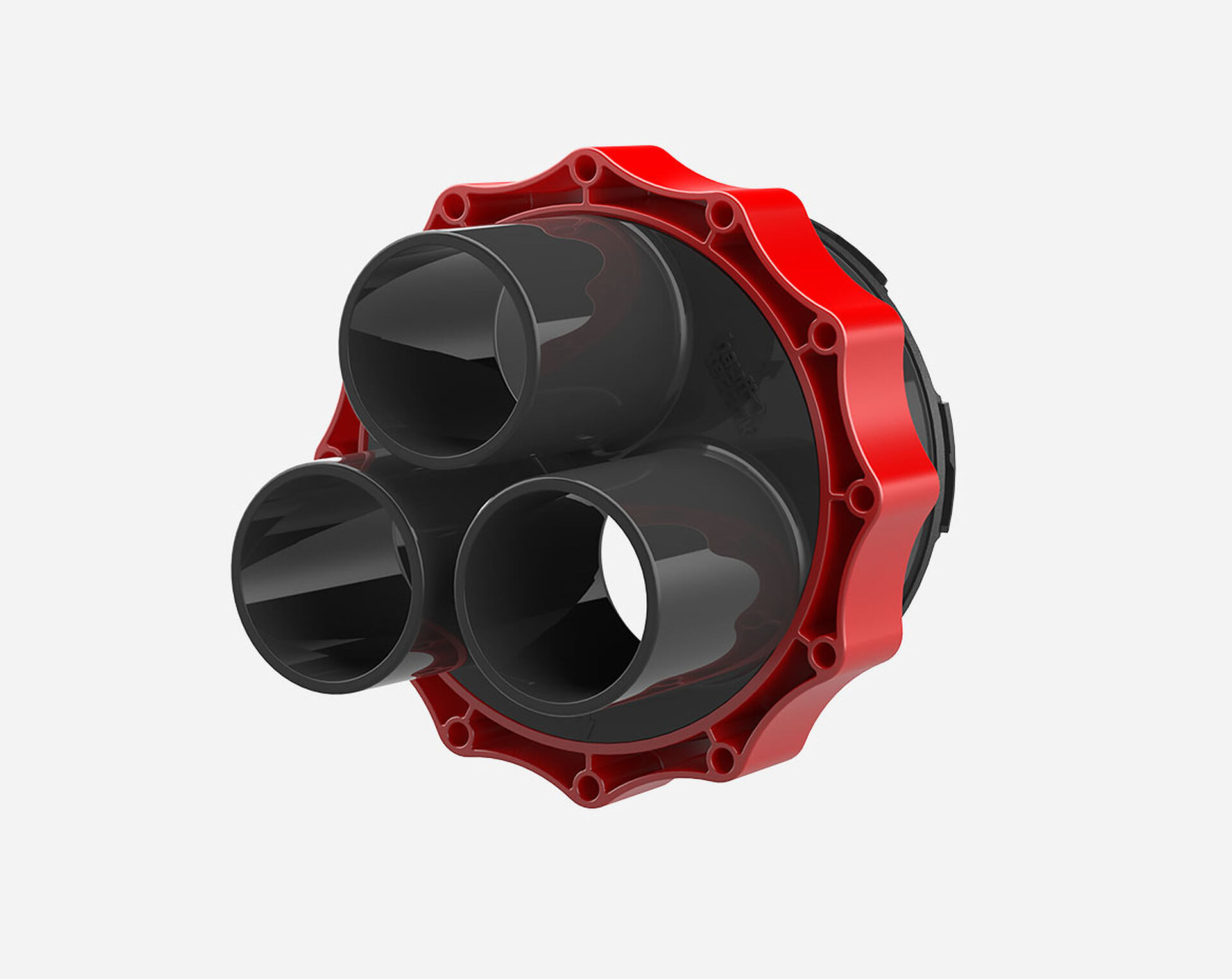

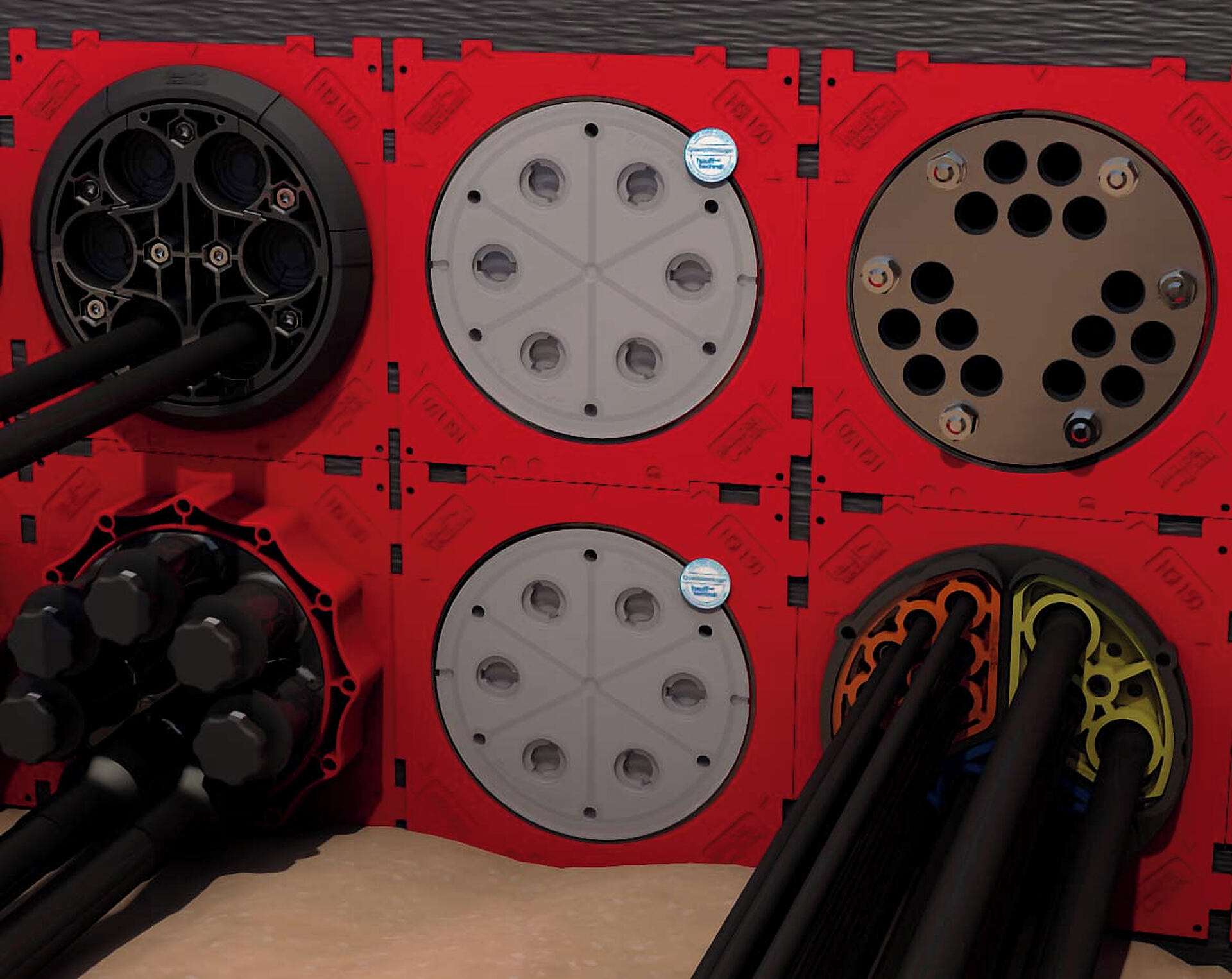

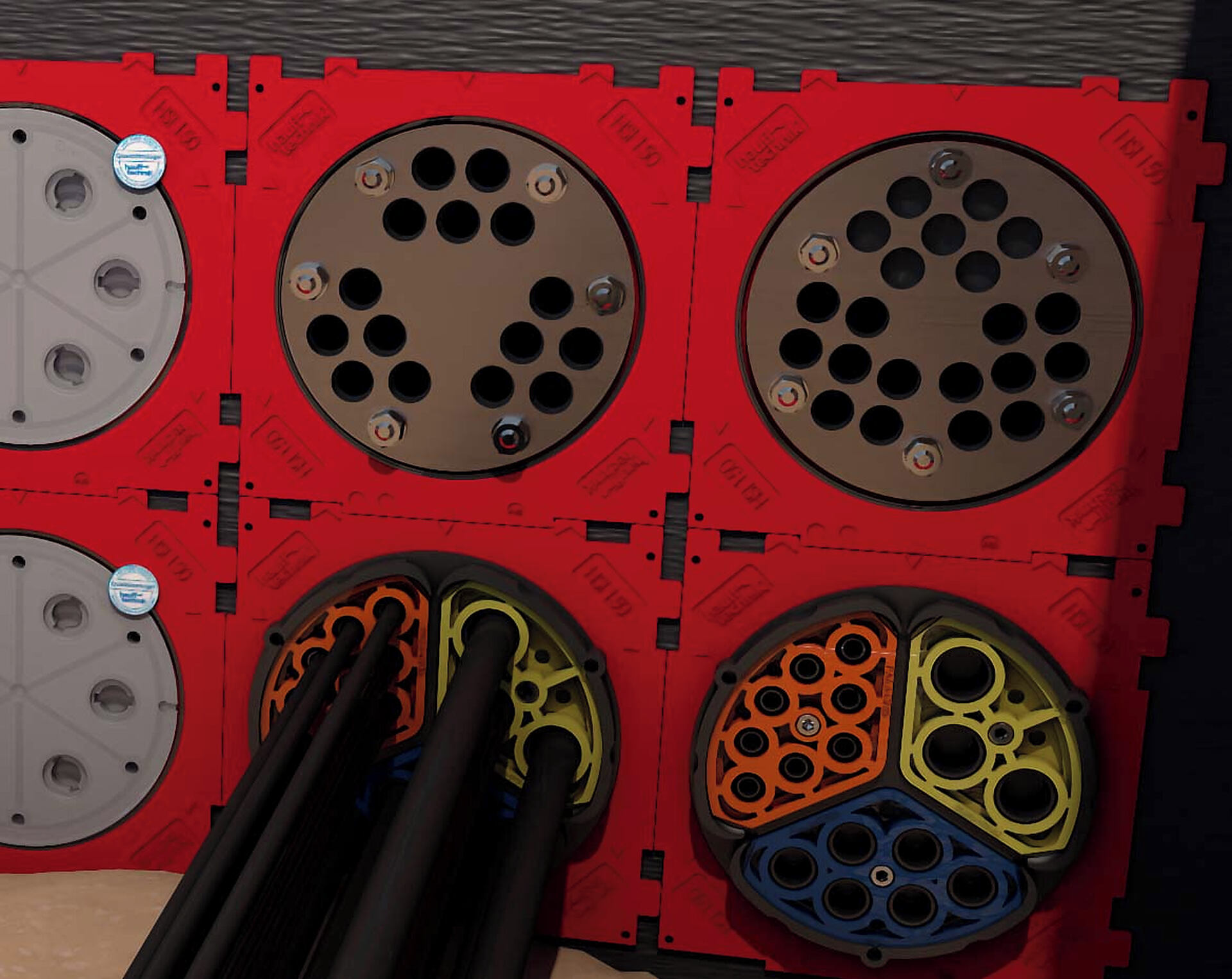

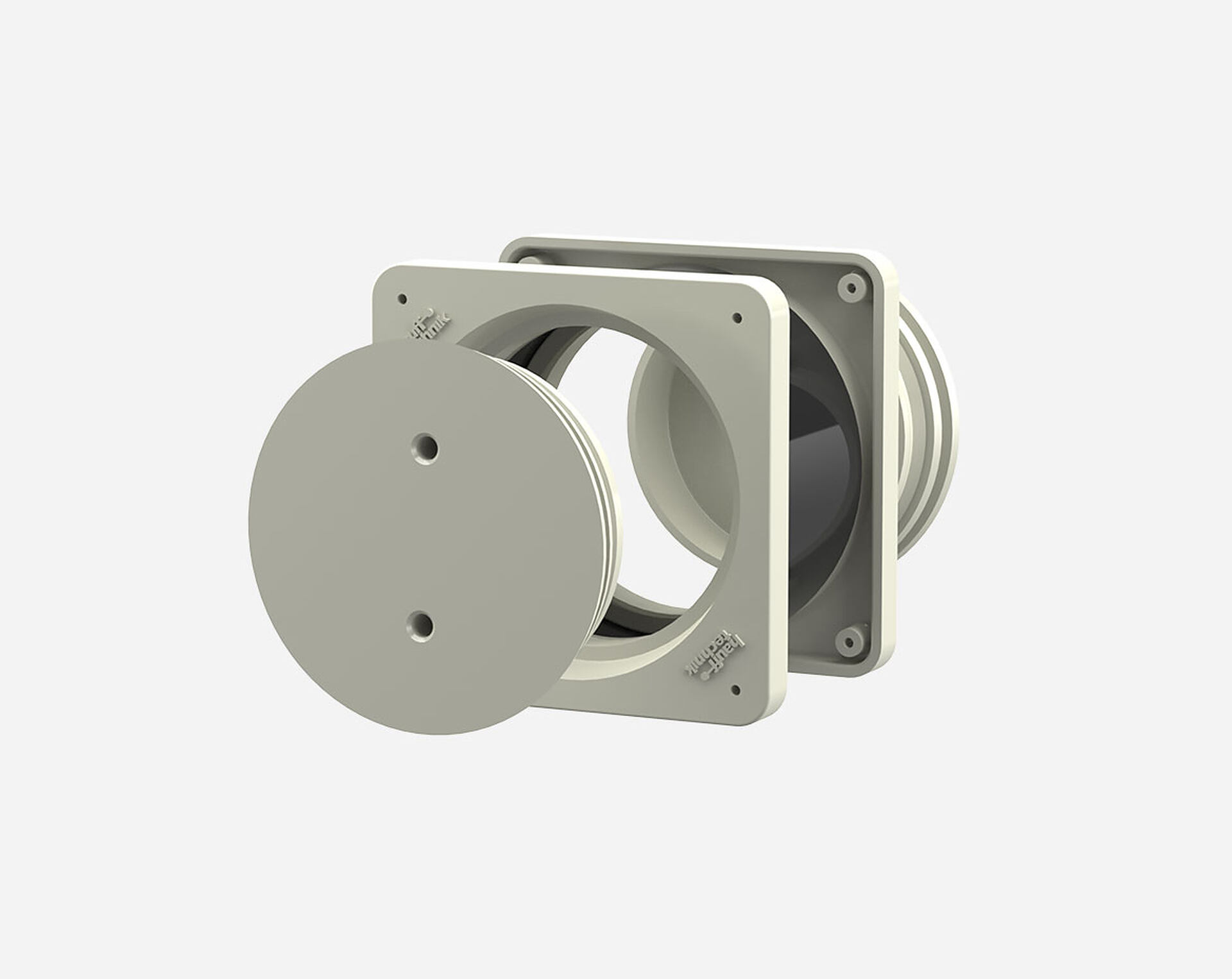

The introduction of electrical cables into houses can be facilitated using multi-service sealing elements, which also accommodate communication lines. These sealing elements are available for both single and multi-service house entries and are compatible with ESH outer pipes and empty conduits for utility line installation in walls. They effectively seal against both the wall pipe and the utility lines.

Using a single empty conduit, up to six different cables can be introduced into the house. This setup allows for some individual lines to remain unconnected initially, ensuring additional interfaces are available for future utility lines. Segment rings are available for cable diameters of 26 to 30 mm, 5 to 8 mm, and 7 to 13 mm.

Grounding Connections by Hauff-Technik for Every Application Scenario

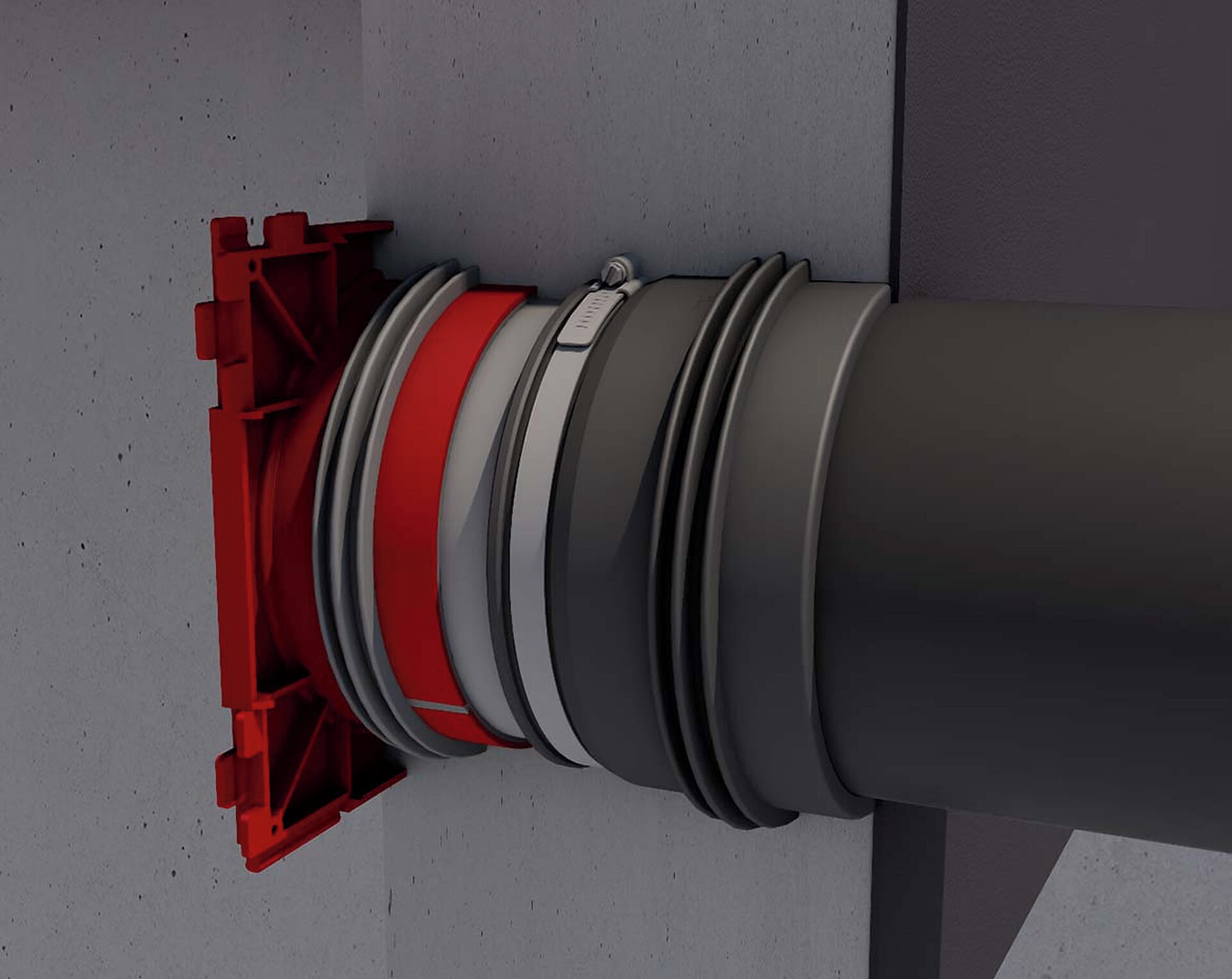

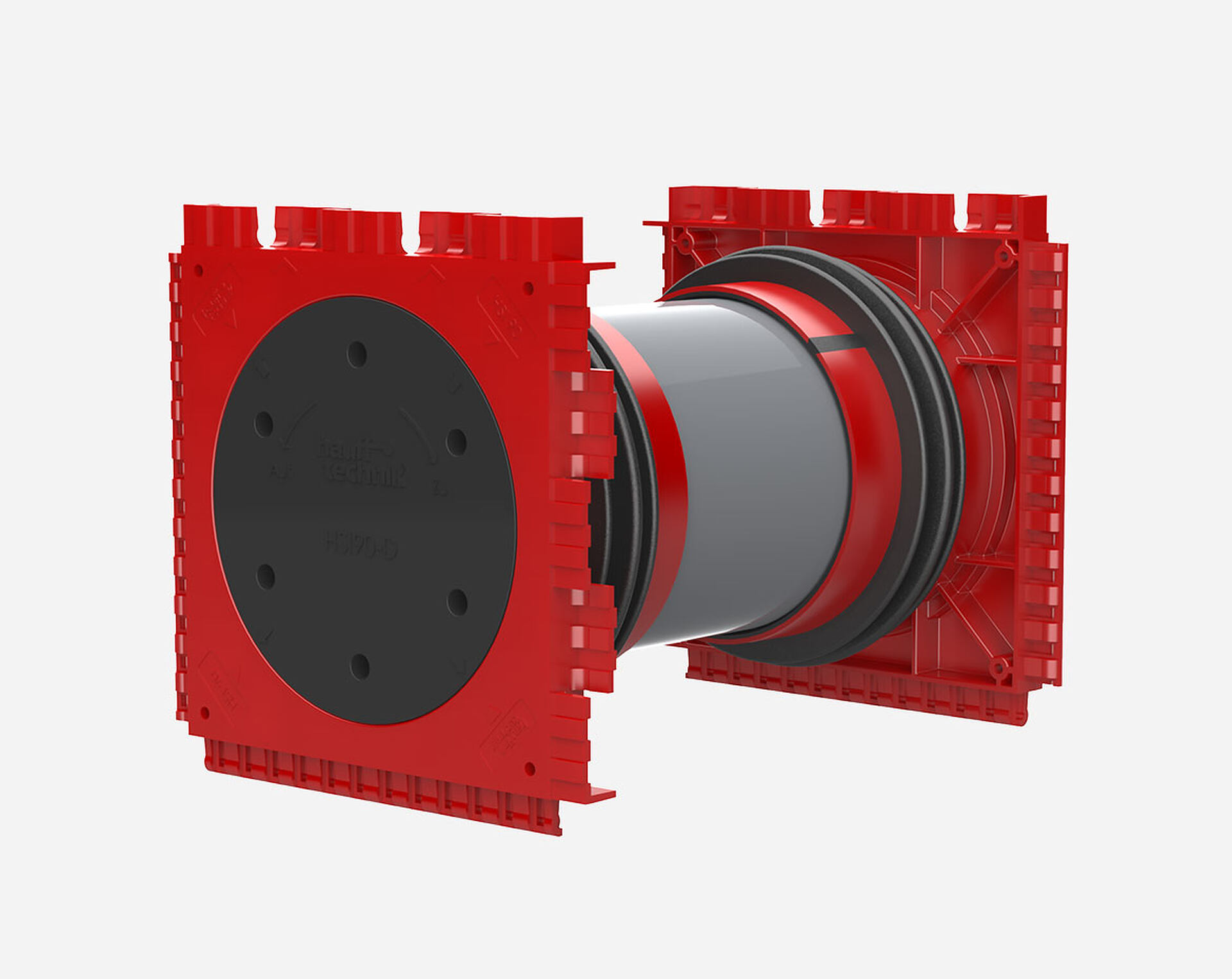

Hauff-Technik provides numerous grounding connection solutions designed for a variety of application scenarios. These solutions primarily differ according to the type of construction. Hauff-Technik offers grounding connections for double and element walls, as well as flush-mounted wall installations in buildings. These connections include external sealing that complies with DIN 18533 and are suitable for structures with black basements.

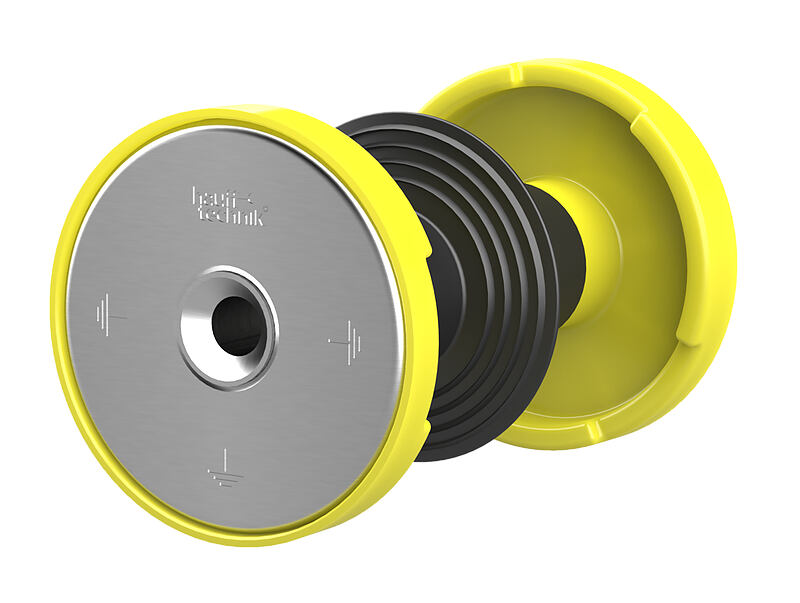

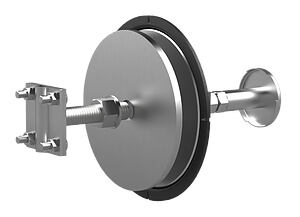

The product range also features flexible grounding connections, where a steel cable establishes the link between two formwork panels, allowing for complete positioning flexibility both inside and outside the building. Moreover, Hauff-Technik's flexible grounding connections include a patented anti-twist mechanism.

These connections are intended for installation during formwork and can also be integrated in precast plants. Hauff-Technik also supplies insulated connections specifically for station construction, providing specialized cross and terminal clamps to ensure proper connection. Additional accessories such as connection bolts and lugs are included.

Hauff-Technik’s grounding connections are designed to resist corrosion and are equipped with waterproof connection threads on both ends. These threads facilitate the grounding connection, streamlining the installation process. All necessary components are included, enabling immediate potential equalization in accordance with current building standards.

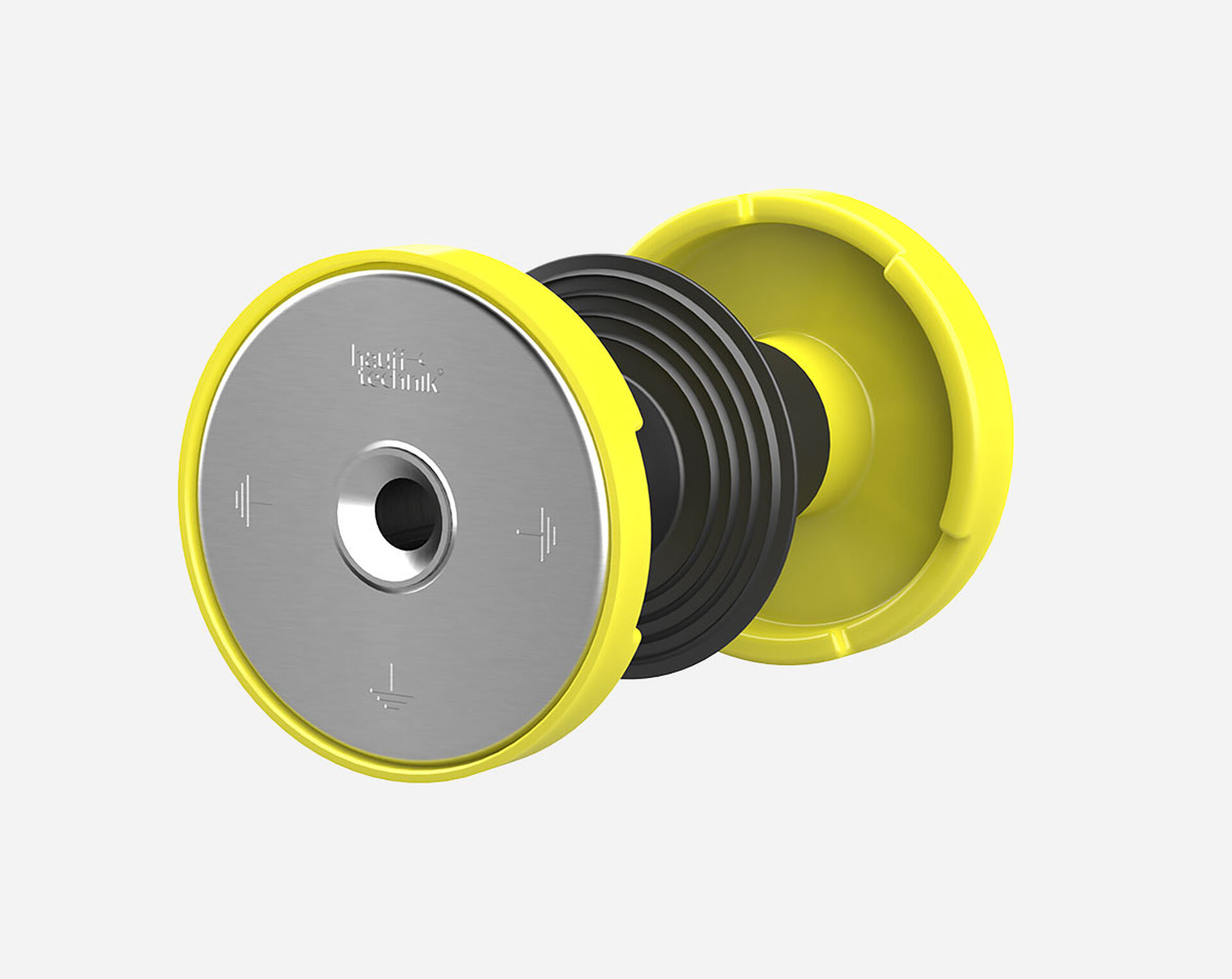

For installing existing deep ground rods, Hauff-Technik offers the right solutions, such as grounding wall collars for round and flat conductors. These collars are suitable for all common types of grounding conductors and feature an integrated water barrier flange that ensures a gas- and watertight transition at the ground level. Grounding wall collars can be utilized in concrete floor slabs or walls as foundation grounding.

Optimally Implementing Retrofitted Grounding Connections

Retrofitting grounding systems in existing structures is a common task, particularly for older buildings where electrical installations often lack proper grounding. Installing a grounding connection is essential during upgrades to ensure safety and compliance.

Typically, this is done with a deep ground rod or a lateral grounding entry through the wall. Hauff-Technik offers various options specifically tailored for walls with perimeter insulation. For wall penetrations, holes with diameters of 18 to 22 mm are sufficient. Inside the building, the grounding connection is made to an electrical cable or flat/round steel, using attachment lugs with cross clamps. Hauff-Technik’s approach simplifies the process of implementing retrofitted grounding connections.

Help us improve our website service.

Where would you place yourself?

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة